Frequently asked questions about our powder coatings

Where can I have metal powder coated?

Our powder coating services are not only available to you in Wettringen, not far from Steinfurt, but we also serve customers from the entire Münsterland region and throughout Germany.

Which industries can I use powder coating for?

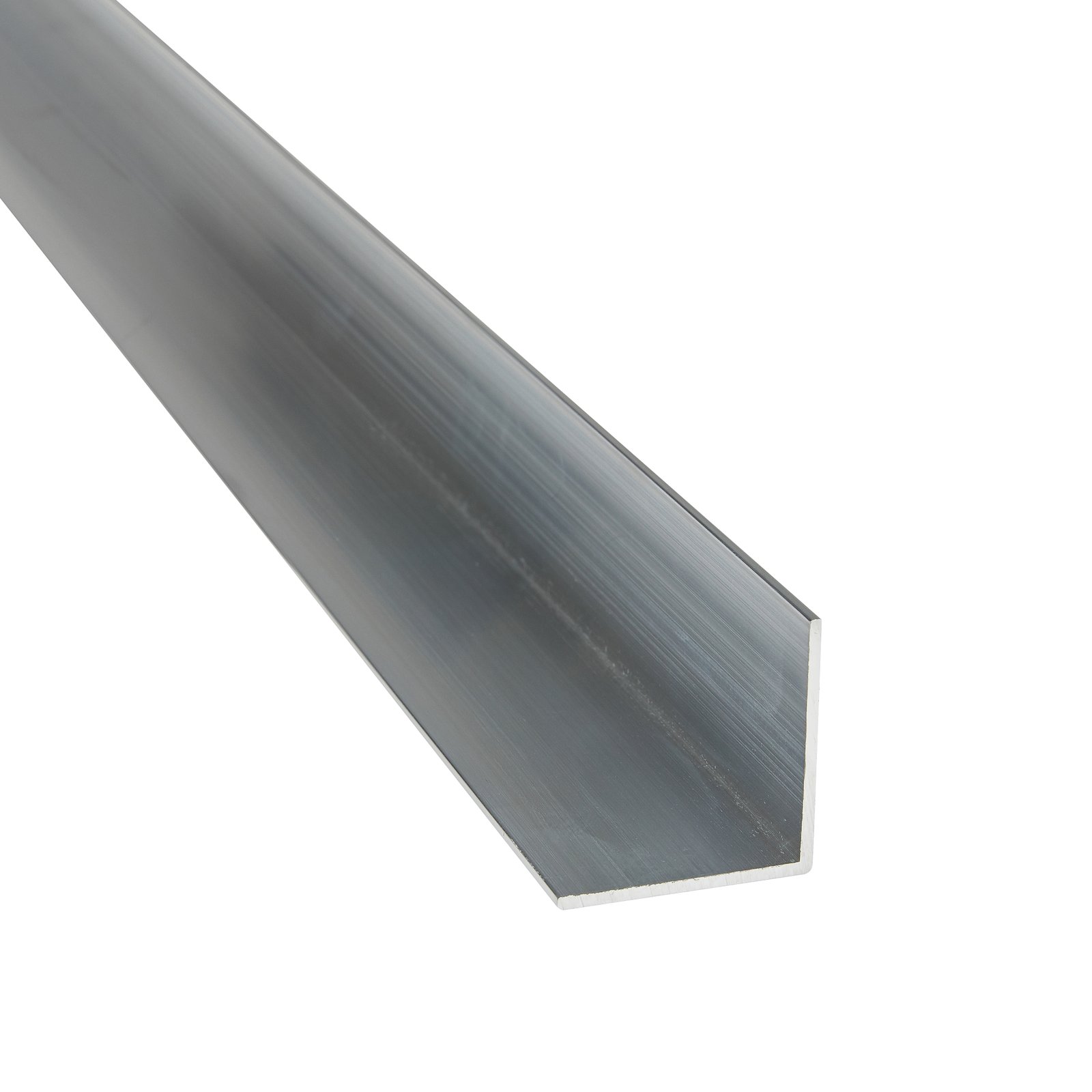

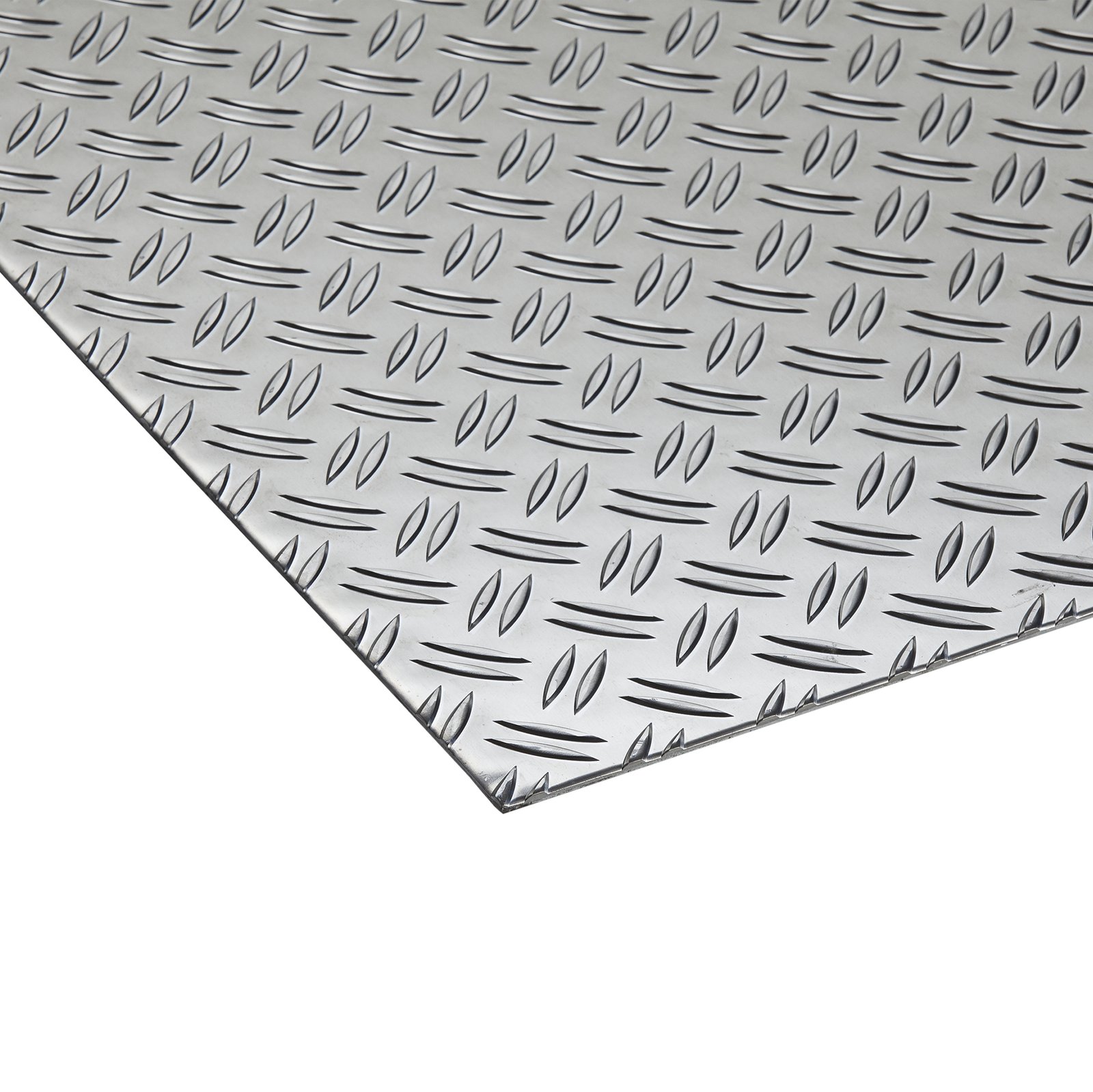

Our range of services extends across various industries, including door and window construction, metal construction, mechanical engineering, locksmiths, the packaging industry, the automotive industry, architecture, exhibition stand construction, lift technology, glazieries, medical technology, façade construction, interior fittings and rail vehicles. Regardless of your area of application, we offer you high-quality solutions.

How sustainable and high-performance are the powder coatings?

In addition to a high-quality appearance, we offer an environmentally friendly process that does not use solvents or heavy metals. Our coatings are characterised by high abrasion resistance, mechanical resilience and excellent corrosion protection. They also offer a good insulation value and allow a choice of different gloss levels and an unlimited variety of colours.

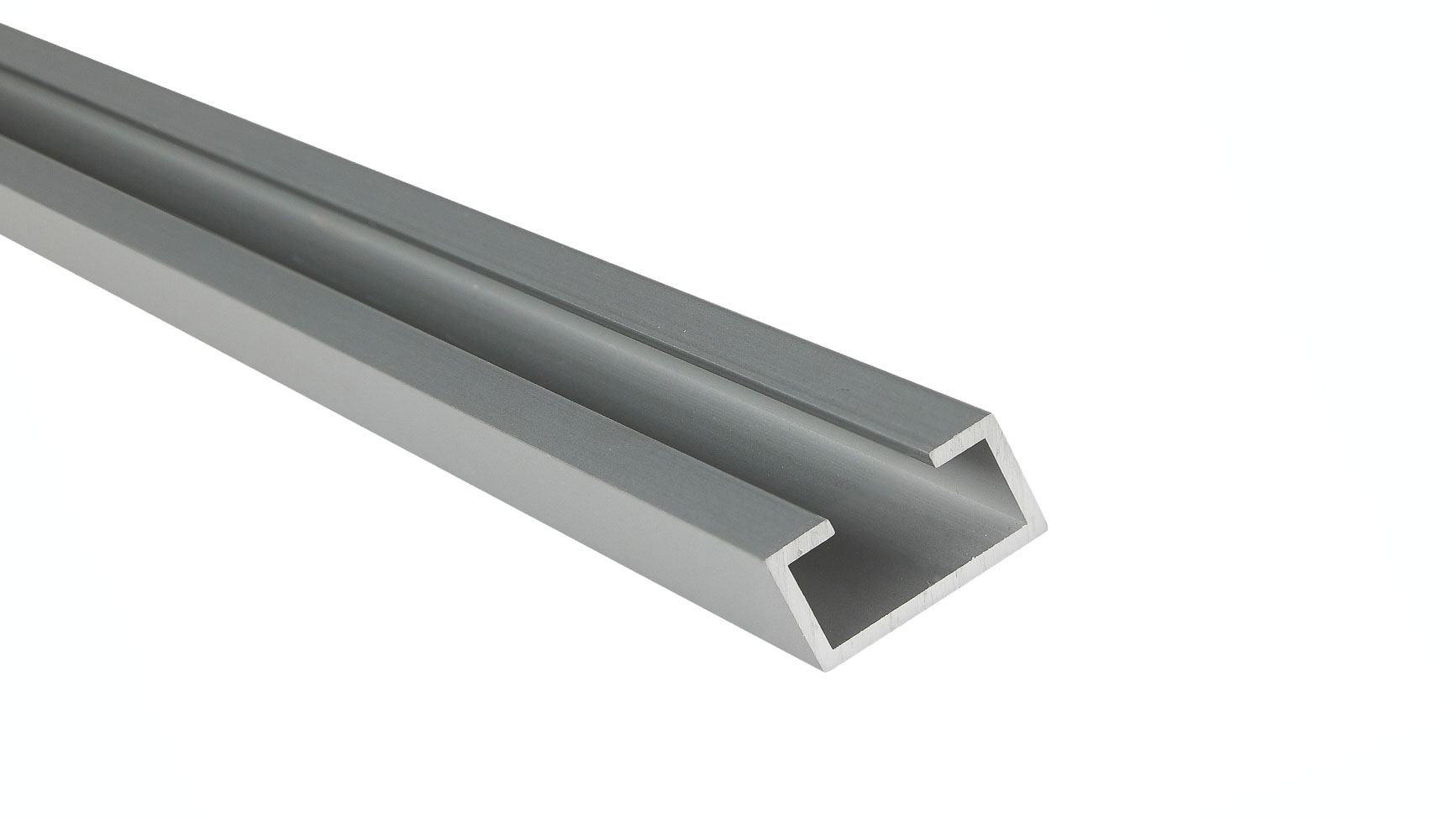

What dimensions can be powder-coated?

Our modern plant technology allows us to coat products with impressive parameters. We can process parts with a length of up to 6 metres, a width of up to 1.80 metres and a height of up to 1.80 metres. Even a unit weight of up to 250 kilograms is no problem for us, and individual dimensions can easily be exceeded thanks to inclined or diagonal guidance.

What are the most common mistakes made with powder coating?

Many manufacturers now offer metals and furniture with powder coating. What is the difference? Many powder coatings are available at low prices, but often at the expense of quality. If the powder coating is applied incorrectly, the following defects are particularly likely to occur:

- Powder layers that are too thin or too thick (visible show-through or coarse surface structure/“orange peel”)

- Beading and edge formation (thick layer build-up at the edges, ‘frame effect’)

- Surface defects caused by electrical flashovers (‘ice flower effect’, small explosions or craters)

- Unreachable, difficult-to-access areas (uneven layer in corners and cavities, ‘Faraday effect’)

- Colour contamination and other soiling (different coloured particles, lubricants or residues)

- Surface bubbles due to outgassing (often occur when workpieces are heated)

If you are aiming for a high-quality look, you should look for high-quality powder coatings and, if necessary, ask the manufacturer for references.

I have special requirements for my powder coating - who can I contact?

Our experienced team is always on hand to provide you with personalised and expert advice on the wide range of powder coating options.